Today’s world is accelerating in all sectors including biology or chemistry with increasing throughput and more precise analysis. Who could have conceived the need for liquid measurements at the microliter scale or lower. Biological and chemical analysis needs to be conducted with higher accuracy than ever and while throughput was significantly extended with the use of multiple available kits, manual handling remains necessary for experiments that cannot be readily automated. Liquid handling is one of the most critical issue for any laboratory addressing biological or chemical manipulations. Nowadays, liquid handling is essentially done using micropipettes that are actuated either manually or electromechanically and equipped with disposable tips. While micro pipetting requires minimal skill, calibration of these important devices can be a challenge to meet the ISO standards and laboratories are most often relying on the outsourcing to specialized companies. However, as micropipettes are delicate devices assessment of their precision and quality are hardly compatible with a year based verification. Up to know, standard verification of the pipette accuracy could be done only using a precision scale with a resolution better than the milligram or, alternatively, by a dilution method with optical density measurements. Thanks to the introduction of revolutionary Atmos device, it is now possible to verify pipettes within less than a minute with uncompromised resolution.

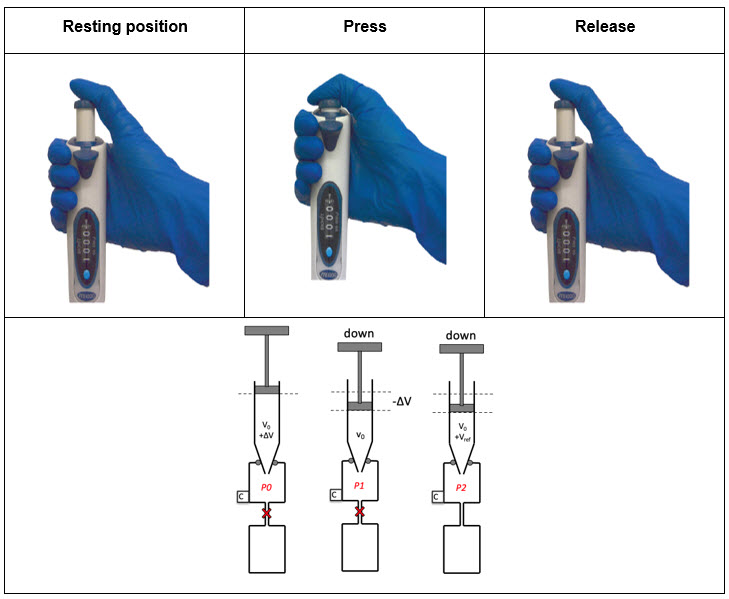

The key of Atmos resides in the use of a physical method that was rendered possible thanks to the development of extremely precise pressure sensors combined with state-of-the-art microelectronics. To understand the Atmos principle, it is necessary to recall that pipetting is done by aspiration of the liquid in the pipette tip, which is itself caused by the displacement of a piston mounted in the core of the device. Actuated by the thumb, or by a small electrical motor, the up and down displacement of the piston acts as in a syringe provoking a difference in pressure that aspirates or pushes the liquid in the tip. Based on the physics principle of perfect gas, Atmos measures the pressure difference caused by the displacement of the plunger in the pipette core.

Accurate determination of the air volume displaced by the plunger is done by measuring the drop of pressure caused by the opening of a reference cavity. Without entering into the calculation of the measurement itself, it is noteworthy to underline the fact that computation is obtained by the relative pressure changes. As a consequence, measurements are independent of the absolute pressure, temperature or humidity conditions. Therefore, unlike gravimetry computation of the true liquid does not need to account for atmospheric pressure, or humidity. Assessing a pipette condition and volume precision is conducted in absence of liquid and can be done in less than a minute. Moreover, the perfect fit of the plastic cone on the pipette can be determined by the leak measurement. As a consequence, it is possible to verify the pipetting adequacy prior to any critical measurement. As precision and stability of the pipetting are key factors in the reproducibility of experiments, Atmos represents an indispensable step forward. First introduced for single pipettes Atmos is now also available for multiple pipettes and a version of eight (8) that are measured in parallel can be purchased.

As Atmos is built using the state of the art technology and equipped with a touch screen, every efforts were made to simplify the user interface. Equipped with a non-volatile memory, Atmos data can be retrieved any time and can be used for internal documentation of the pipette qualities. With a connected printer, results can be printed immediately for GLP compliance.

Additional features including a molarity calculator, single or cascade dilutions provides additional tools for the day to day life rendering Atmos the perfect companion for any laboratory.

By Prof. Daniel Bertrand, PhD, Chief Technology Officer at UniPix

Contact:

UniPix GmbH | Bei den Pferdeställen 3 | 72072 Tübingen | Germany

Phone:+49-7071-777 2818